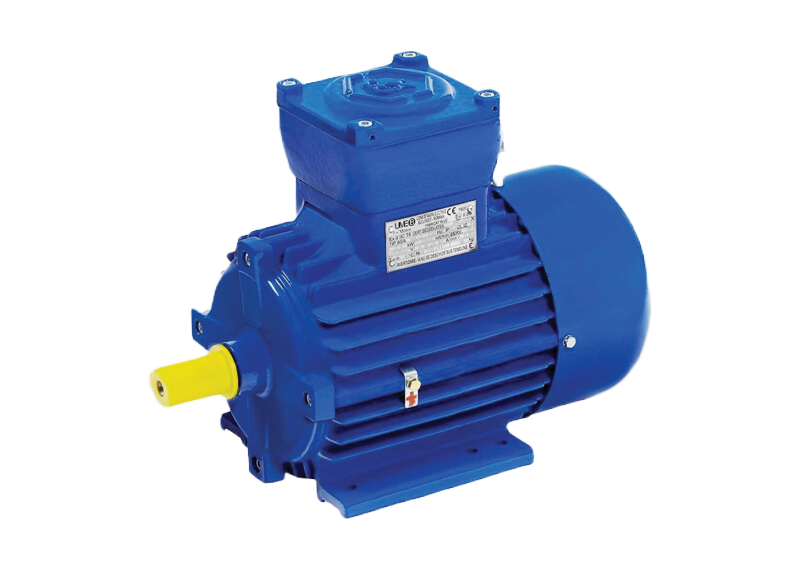

Explosion proof motors are required for industrial applications with the presence of highly combustible, pervasive materials. Explosion proof does not mean that the motor will never explode, nor that it is immune from external

explosions. Rather, an explosion proof motor has features that prevent an internal motor explosion from igniting a larger, ambient, combustible atmosphere.

Explosion proof motors are distinguished by high material quality,

robust design, high index of IP protection, bearings greased for life, weather and corrosion resistant final overcoat and high dielectric strength insulation system intended to be feed by static frequency converter. Local conditions

must be divided in danger zones, defined by end user together with appropriate establishment, according to frequency and duration of appearance of an explosive gas atmosphere.

Typical customer applications that are in (Class I) environments (flammable gases & vapors) include:

Spray painting and finishing area

Utility gas plants

Petroleum refining plants

Dry cleaning facilities

Dip tanks containing combustible or flammable fluids

Plant facilities extracting solvents

Process facilities manufacturing or using nitro-cellulose

Gas Station

Typical customer applications that are in (Class II) environments (combustible dust) include:

Flour & Feed mills

Fire work plants and storage areas

Magnesium manufacturing and storage areas

Coal preparation and handling facilities

Pulverized sugar and cocoa manufacturing plantss

Packaging and storage plants

Spice grinding and storage plants

© 2023 TechEngineering All Rights and Wrongs Reserved.