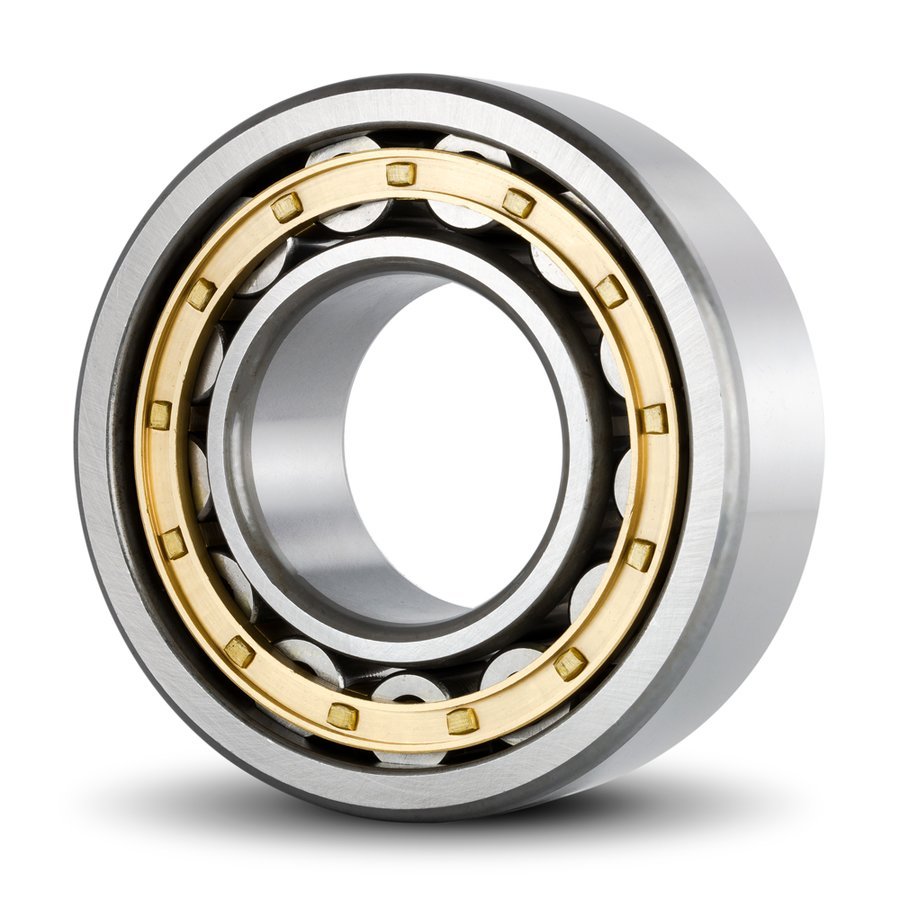

The inner and outer rings of Tapered roller bearings have tapered raceways, and the rollers are also tapered. If the cone is extended, its apex will intersect at a point on the bearing axis. Therefore, the rollers of tapered roller bearings

can achieve pure rolling on the raceway.

Tapered roller bearings are separable bearings. The inner components of the bearing (composed of rollers, cage and inner ring) and outer ring can be separated, so it can be easily installed on the journal and bearing seat.

Single row tapered roller bearings can bear axial load in one direction. And can limit the axial displacement of the shaft relative to the bearing seat in one direction. Even under the action of pure radial load, the tapered roller bearing will generate additional axial component force inside. At this time, an equal amount of reaction force is required to balance it. Usually two single-row tapered roller bearings of the same structure are used in the two supports to face-to-face or back-to-back installation.

Double row tapered roller bearings can bear axial load in both directions while bearing radial load. The clearance has been adjusted before the product leaves the factory, so it can be directly installed and used without adjusting the clearance. Double row tapered roller bearings can limit the axial displacement of the bearing in two directions relative to the bearing seat within the axial clearance of the bearing.

The performance of Four row tapered roller bearings is basically the same as that of double row tapered roller bearings, but the ability to bear radial loads is greater than that of double row tapered roller bearings. The limiting speed

is low, and it is mainly used for heavy machinery, such as rolling mills.

Bearing Company can also provide customers with tapered roller bearings of other structures, such as sealed tapered roller bearings and other products.

© 2023 TechEngineering All Rights and Wrongs Reserved.