Most of Cylindrical roller bearings are separable bearings, which are very convenient for installation and disassembly. Cylindrical roller bearings can withstand larger radial loads and are suitable for use in high-speed running situations. This kind of bearing can make the angular error between the inner shaft and the outer shaft small, ranging from 2’to 4′. Therefore, it requires higher machining accuracy on the shaft and bearing seat; otherwise, the asymmetric load and stress will be concentrated on the position of the raceway. This situation can be improved by correcting the contact bus bars of the rollers or raceways. Cylindrical roller bearings are divided into single row, double row and multiple row cylindrical rollers according to different rows.

Most of Cylindrical roller bearings are separable bearings, which are very convenient for installation and disassembly. Cylindrical roller bearings can withstand larger radial loads and are suitable for use in high-speed running situations.

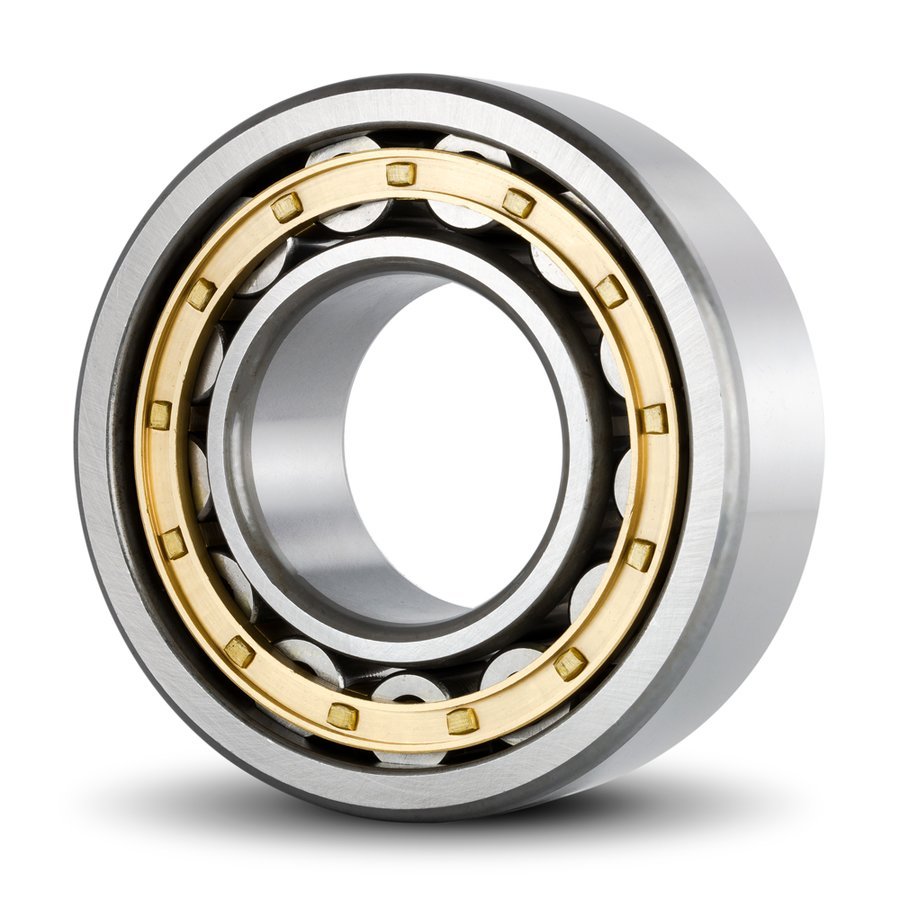

Single row cylindrical roller bearings are composed of four parts: inner ring, outer ring, roller and cage. This type of bearing allows the angular error (inclination) between the axis of the inner ring and the axis of the outer ring

to be very small, only 2’~4′. Therefore, the machining accuracy of the shaft and the bearing seat is relatively high, otherwise, uneven load or stress concentration will easily occur at the contact parts of the raceway. But after correcting

the roller or raceway contact bus bar, the occurrence of stress concentration can be reduced. Single row cylindrical roller bearings include N, NU, NJ, NF, NUP, NFP, NH type.

Double row cylindrical roller bearings have two structures: cylindrical inner bore and conical inner bore (the bearing code is added with K). The bearing has the advantages of compact structure, high rigidity, large carrying capacity, and small deformation after being loaded. It is especially suitable for the support of machine tool spindles. The conical inner hole can also play the role of micro-adjustment of the clearance, and can simplify the structure of the positioning device and facilitate installation and disassembly. Commonly used Double row cylindrical roller bearings are: NN, NNU, NNF type.

Four-row cylindrical roller bearings are mainly used in rolling mill machinery such as cold and hot rolling mills and opener mills. The bearing is of a separate structure, and the bearing ring and rolling element components can be easily separated. Therefore, the bearing is cleaned and inspected. Or installation and disassembly are very convenient. Four-row cylindrical roller bearings include FC and FCD types.

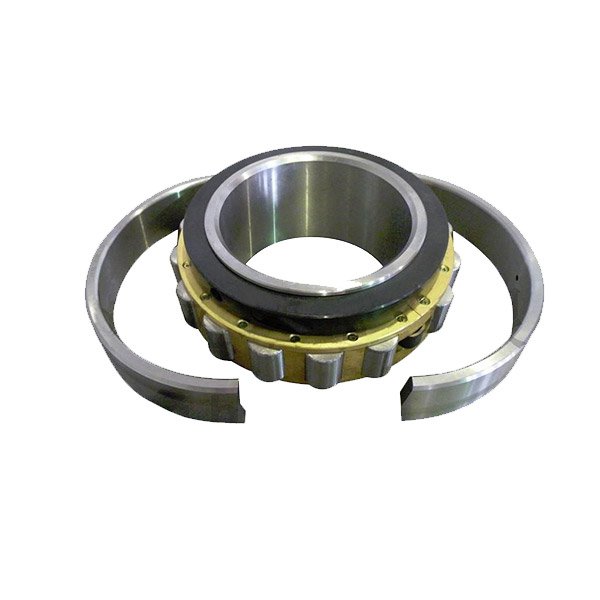

Split cylindrical roller bearings have a row of cylindrical rollers and cylindrical inner and outer ring raceways. Split cylindrical roller bearings are used for rolling machinery that is very difficult to install, disassemble and maintain. They are usually installed in boxes suitable for different types of enclosures. Split cylindrical roller bearings have a wide range of products and can be used in many different industries, from the light and compact 100 series (which can achieve high operating speeds) to the 03/03E series (which can be used in extreme load conditions).

© 2023 TechEngineering All Rights and Wrongs Reserved.